Tungsten Carbide Hnav Rings rau Kev Lag Luam Roj thiab Roj Av

Kev Piav Qhia Luv:

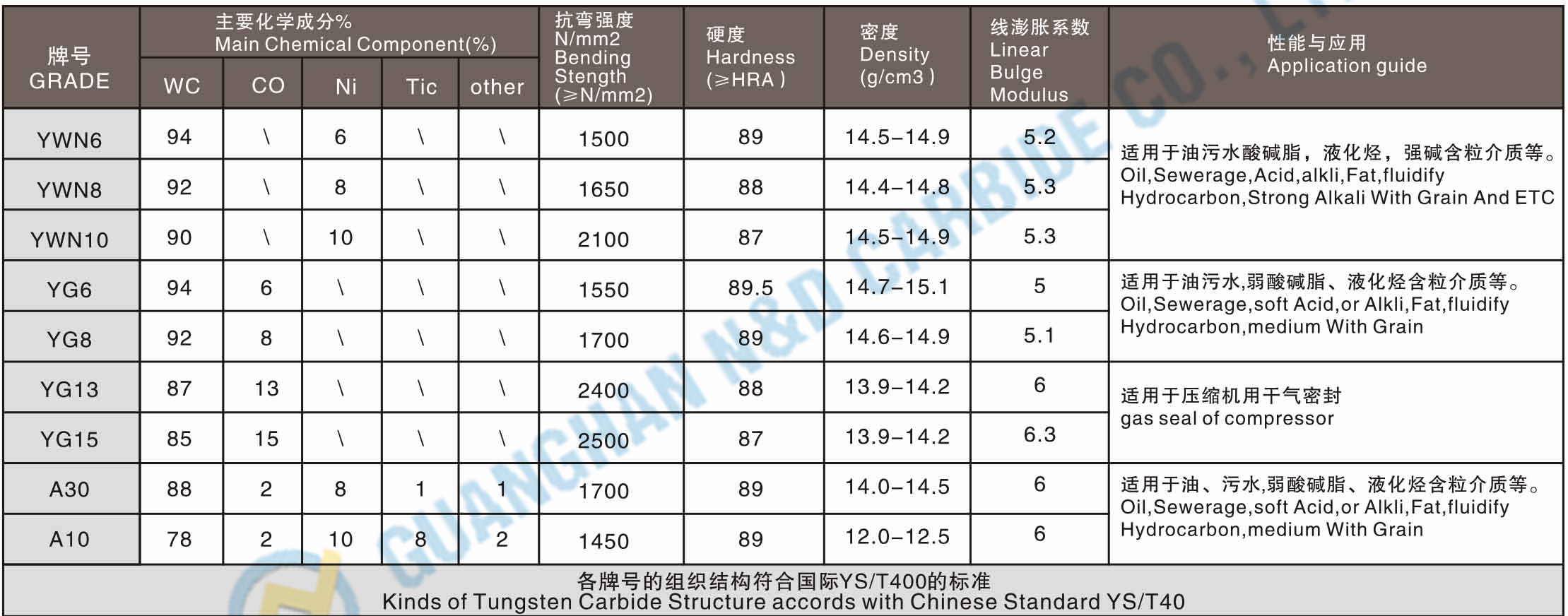

* Tungsten Carbide, Nickel/Cobalt Binder

* Cov Cub Sinter-HIP

* CNC Machining

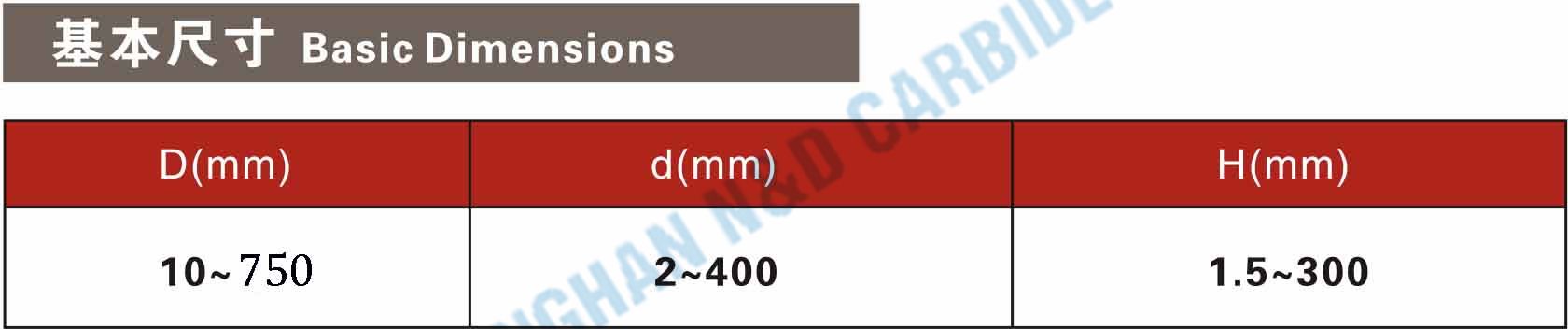

* Sab nraud txoj kab uas hla: 10-750 hli

* Sintered, tiav tus qauv, thiab daim iav lapping;

* Muaj ntau qhov ntau thiab tsawg, kev kam rau siab, qib thiab ntau npaum li cas thaum thov.

Lub nplhaib tungsten carbide hnav tau tsim los rau kev ruaj khov tsis muaj qhov sib piv hauv qhov kub siab, kub siab, thiab qhov chaw corrosive. Ua tus thawj coj hauv kev daws teeb meem khoom siv siab heev, peb xa cov nplhaib foob uas tau tsim los ntawm kev ua haujlwm zoo uas txhais dua qhov kev ua tau zoo hauv kev siv hauv kev lag luam.

Cov nplhaib hnav Tungsten Carbide siv dav ua lub ntsej muag foob hauv cov foob pob rau cov twj tso kua mis, cov tshuab sib tov thiab cov khoom sib xyaw uas pom muaj nyob rau hauv cov chaw ua roj, cov nroj tsuag petrochemical, cov nroj tsuag chiv, cov chaw ua cawv, kev khawb av, cov chaw ua pulp, thiab kev lag luam tshuaj. Lub nplhaib foob yuav raug ntsia rau ntawm lub cev twj tso kua mis thiab lub qag tig, thiab tsim los ntawm lub ntsej muag kawg ntawm lub nplhaib tig thiab zoo li qub ua lub foob kua lossis roj.

Cov xwm txheej ntawm daim ntawv thov

- Roj thiab Roj Av: Cov khoom siv khawb av, cov cuab yeej downhole, thiab cov foob kav dej.

- Kev Ua Tshuaj: Cov twj tso kua mis, cov reactors, thiab cov li qub uas tuav cov kua dej uas muaj zog.

- Cov Tshuab Siv Hauv Kev Lag Luam: Compressors, turbines, thiab hydraulic systems.

- Tub Rog: Cov khoom siv hauv qab dej hiav txwv thiab cov khoom siv tiv taus dej ntsev.

Muaj ntau qhov ntau thiab tsawg thiab hom ntawm lub nplhaib tungsten carbide, peb kuj tuaj yeem pom zoo, tsim,tsim, tsim cov khoom raws li cov duab kos thiab cov kev xav tau ntawm cov neeg siv khoom.

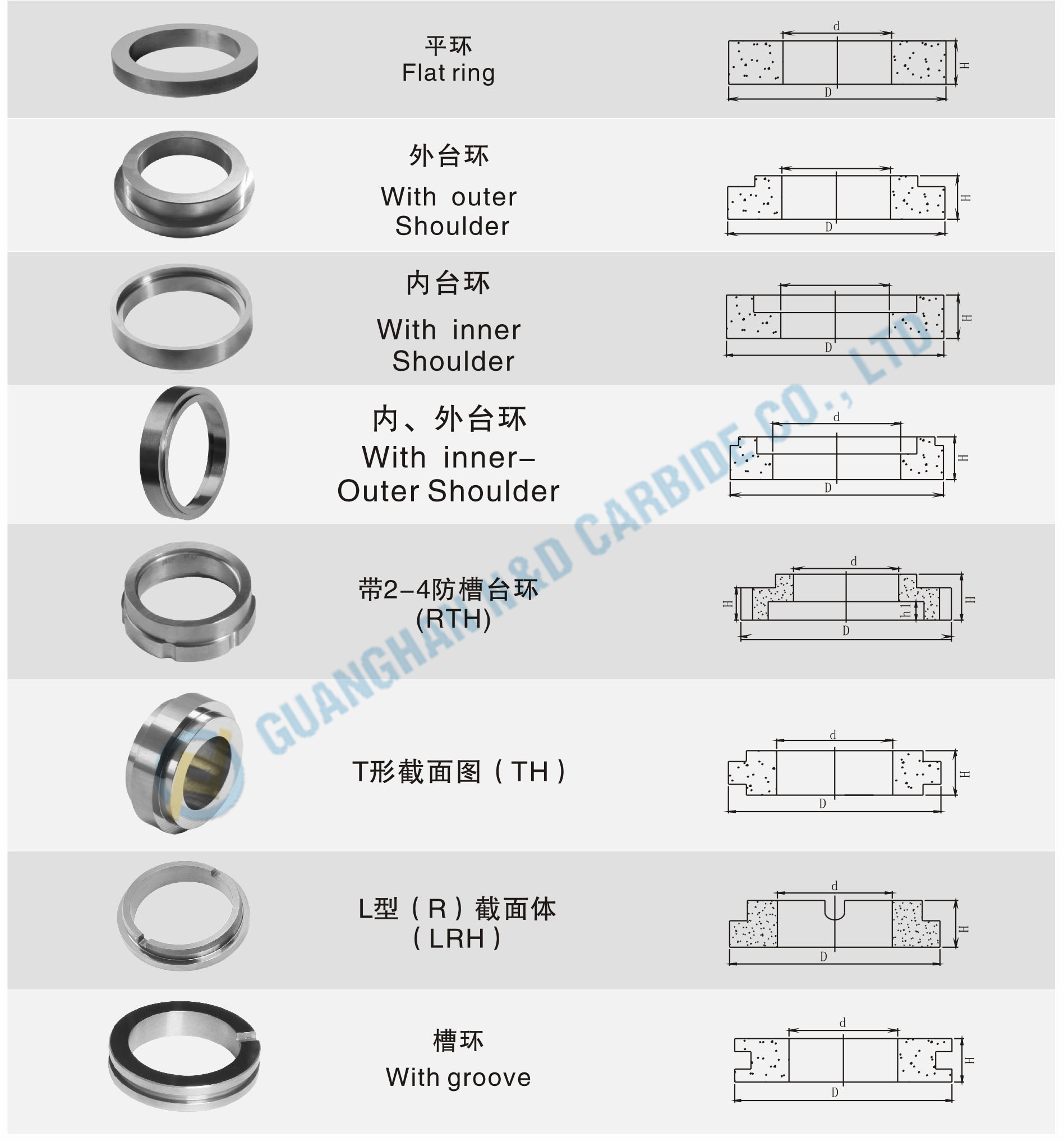

Tungsten carbide hnav cov nplhaib tau tsim los ntawm ntau yam duab los hloov kho rau cov khoom siv sib txawv.

Rau koj qhov yooj yim, ntawm no yog qee hom TC rings uas siv ntau:

Kev Tiv Thaiv Kev Hnav Tsis Sib Xws

Lub nplhaib tungsten carbide hnav zoo dua li hlau thiab ceramics hauv cov chaw ua haujlwm abrasive, ua kom cov khoom poob tsawg kawg nkaus thiab lub neej ua haujlwm ntev. Nws qhov nyuaj heev (Mohs 9-9.5) ua rau nws zoo tagnrho rau cov xwm txheej siab-kev sib txhuam.

Kev tiv thaiv corrosion

Tsim los rau kev ua tshuaj lom neeg thiab kev siv hauv hiav txwv, lub nplhaib hnav tungsten carbide tiv taus cov kua dej thiab dej ntsev, tiv thaiv kev puas tsuaj thiab kev pheej hmoo xau.

Thermal Stability

Tswj tau qhov ruaj khov ntawm cov qauv txog li 500 ° C, ua kom lub nplhaib tungsten carbide ruaj khov thiab tsis hloov pauv thaum ua haujlwm kub siab.

Lub Neej Ntev Dua

Txo lub sijhawm tsis ua haujlwm txij nkawm los ntawm 50%+ piv rau cov foob pob ib txwm muaj, txiav cov nqi ua haujlwm thiab txhawb kev ua haujlwm zoo hauv kev lag luam xws li roj & roj thiab kev khawb av.

Kev kho kom haum

Cov qauv geometries thiab cov npoo tiav ua kom zoo dua lub nplhaib hnav tungsten carbide rau cov kev xav tau tshwj xeeb, los ntawm kev ua haujlwm precision mus rau kev tswj cov kua dej siab.

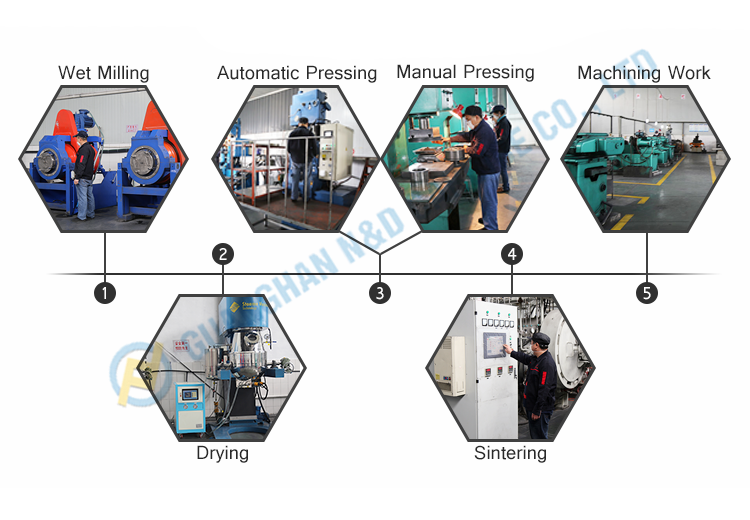

- Kev Npaj Khoom Siv: Hmoov tungsten carbide uas muaj purity siab yog sib xyaw nrog cobalt binder rau qhov nyuaj thiab tawv tshaj plaws.

- Kev Nias & Sintering: Kev nias siab siab ua raws li kev tswj hwm sintering ua kom muaj qhov porosity tsawg kawg nkaus thiab qhov ceev zoo dua.

- Kev Ua Kom Tseeb: Kev sib tsoo uas tswj los ntawm lub khoos phis tawj ua tiav qhov tseeb ntawm qib micron rau qhov chaw sib khi zoo meej.

- Kev Kho Mob Nto: Cov txheej txheem xaiv tau txhim kho kev tiv thaiv corrosion thiab txo kev sib txhuam.

Guanghan ND Carbide tsim ntau yam khoom siv tungsten carbide uas tiv taus kev hnav thiab tiv taus corrosion.

cov khoom sib xyaw.

* Cov nplhaib foob tshuab

* Cov Bushings, Cov Tes Tsho

* Tungsten Carbide Nozzles

*AP| Pob thiab Rooj Zaum

* Choke qia, Lub rooj zaum, Tawb, Disk, Flow Trim ..

*Tungsten Carbide Burs/ Rods/Phaj/Strips

* Lwm yam kev cai tungsten carbide hnav qhov chaw

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Peb muab ntau yam carbide qib hauv ob qho tib si cobalt thiab nickel binders.

Peb ua txhua yam txheej txheem hauv tsev ua raws li peb cov neeg siv khoom cov duab kos thiab cov ntaub ntawv qhia. Txawm tias koj tsis pom los xij

nws daim ntawv teev npe ntawm no, yog tias koj muaj lub tswv yim peb yuav tsim tawm.

Q: Koj puas yog lub tuam txhab lag luam lossis chaw tsim khoom?

A: Peb yog cov chaw tsim khoom ntawm tungsten carbide txij li xyoo 2004. Peb tuaj yeem muab 20 tons tungsten carbide khoom ibhli. Peb tuaj yeem muab cov khoom carbide raws li koj xav tau.

Q: Koj lub sijhawm xa khoom ntev npaum li cas?

A: Feem ntau nws yuav siv sijhawm 7 txog 25 hnub tom qab kev txiav txim paub meej. Lub sijhawm xa khoom tshwj xeeb nyob ntawm cov khoom tshwj xeebthiab qhov ntau koj xav tau.

Q: Koj puas muab cov qauv? Puas yog pub dawb los yog them?

A: Yog, peb tuaj yeem muab cov qauv dawb xwb tab sis cov nqi thauj khoom yog nyob ntawm cov neeg siv khoom.

Q. Koj puas sim tag nrho koj cov khoom ua ntej xa khoom?

A: Yog, peb yuav ua 100% kev kuaj thiab tshuaj xyuas peb cov khoom cemented carbide ua ntej xa khoom.

1. Lub Hoobkas Nqe;

2. Ua kom pom tseeb cov khoom siv carbide tsim khoom rau 17 xyoo;

3.lSO thiab AP | chaw tsim khoom pov thawj;

4. Kev pabcuam tshwj xeeb;

5. Zoo zoo thiab xa khoom sai;

6. HlP cua sov sintering;

7. CNC machining;

8. Tus neeg muab khoom ntawm Fortune 500 lub tuam txhab;